Dependable Industrial Scales Constructed for Heavy-Duty Applications

Dependable Industrial Scales Constructed for Heavy-Duty Applications

Blog Article

Enhance Your Organization Workflow With Reliable Industrial Scales

In today's competitive landscape, the accuracy of industrial ranges plays an essential function in boosting total business operations. Accurate evaluating not just reduces pricey inconsistencies throughout numerous fields, such as manufacturing and logistics, however additionally makes certain compliance with stringent industry criteria. As companies look for to enhance performance, understanding the different kinds of ranges and their technological developments ends up being necessary. However, the selection process can be intricate, and the ramifications of these options can substantially impact functional success. What elements should be taken into consideration to guarantee the ideal tools is chosen for your specific demands?

Significance of Accurate Considering

Exact considering is critical in various commercial applications, as also minor disparities can bring about substantial financial losses and operational inefficiencies. Industries such as manufacturing, logistics, and food processing depend on specific measurements to make certain product top quality, governing compliance, and optimum resource management. Inaccurate weights can lead to overflow, waste of basic materials, or inadequate supply, affecting profitability and customer contentment.

Moreover, accurate considering is necessary for safety and security and ecological compliance. In the chemical sector, wrong dimensions can lead to improper mixes, resulting in harmful situations or lawful ramifications. Additionally, in the food sector, specific evaluating is vital for sticking to nutritional labeling requirements, guaranteeing that consumers get precise information pertaining to the items they buy.

The integration of trusted industrial ranges not only improves functional efficiency but likewise sustains data-driven decision-making. Firms that focus on specific considering can maximize stock management, enhance supply chains, and decrease expenses related to returns and rework. Spending in top notch commercial evaluating options is crucial for services aiming to keep a competitive edge in today's vibrant market. Accurate considering eventually works as a structure for operational quality and sustainable development.

Kinds Of Industrial Scales

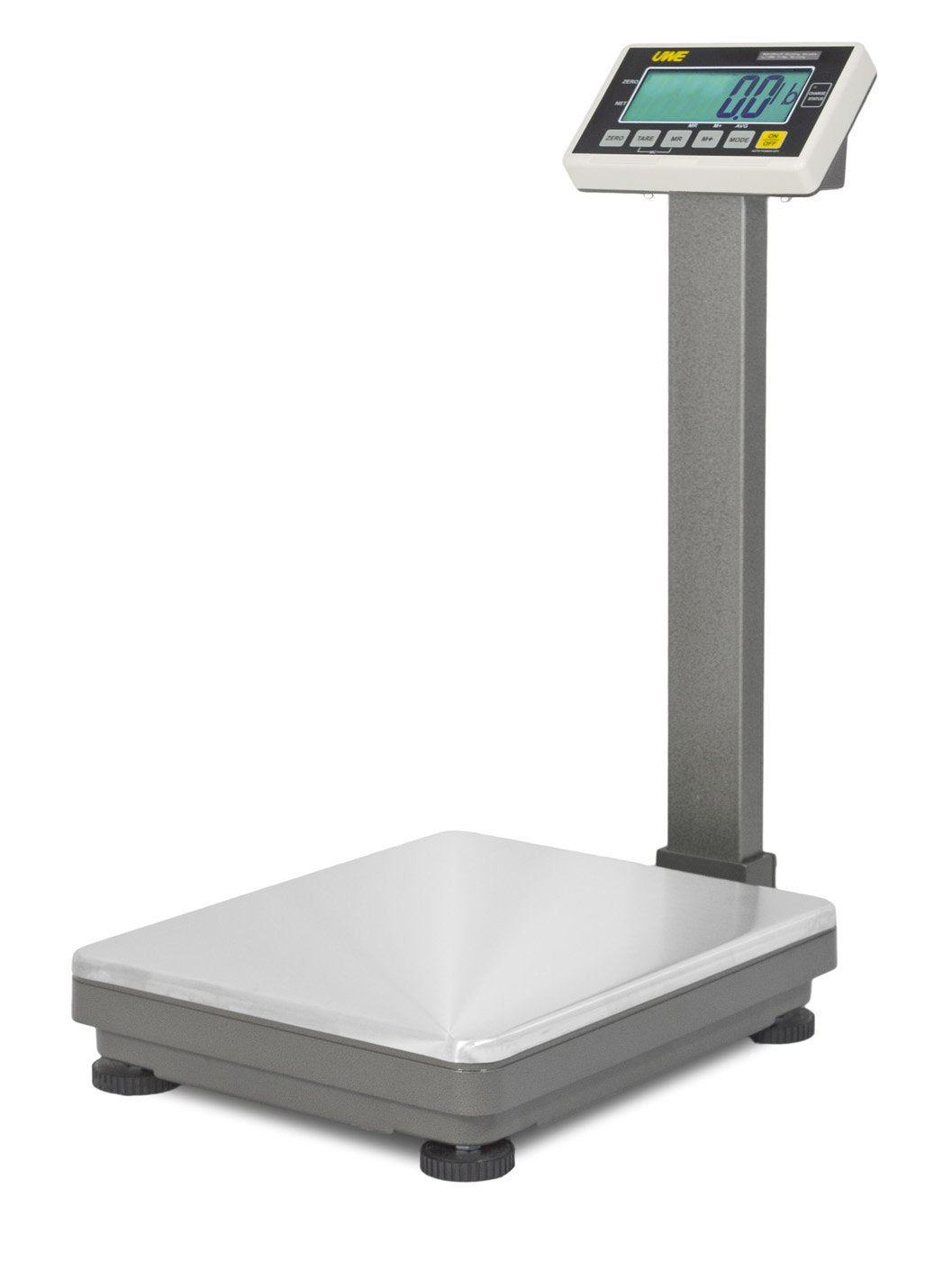

Industrial scales come in numerous types, each made to satisfy particular evaluating requirements across different fields. Amongst the most common kinds are platform ranges, which offer a large evaluating surface area appropriate for heavy products, making them ideal for storage facilities and making facilities. These ranges often feature electronic display screens for easy reading.

An additional kind is bench scales, which are normally smaller sized and portable, best for usage in laboratories or retail atmospheres. They permit quick measurement of smaller products while keeping accuracy. For applications needing the considering of fluids, storage tank ranges are specifically created to gauge the weight of tank, making sure specific inventory management.

Crane ranges are also notable; they are put on hold from a framework to weigh hefty materials in industrial settings. Each kind of industrial range offers a distinct objective, boosting operational efficiency throughout diverse sectors.

Advantages of Modern Modern Technology

Additionally, modern industrial ranges typically come equipped with connectivity features that allow smooth integration with various other systems, such as inventory administration and production tracking. This interconnectivity promotes an extra cohesive process and minimizes downtime, as services can monitor performance metrics and make data-driven choices promptly.

Additionally, lots of contemporary scales use customizable settings and straightforward user interfaces, enabling drivers to adapt their equipment for certain functional demands. Boosted sturdiness and strength versus rough ecological problems further contribute to the durability and integrity of modern-day scales, ensuring they can endure the rigors of industrial usage.

Picking the Right Tools

Various sectors might call see this page for distinct kinds of scales, such as floor ranges for hefty lots, bench ranges for smaller sized things, or mobile ranges for flexibility. Additionally, thinking about the environment in which the scales will be used is important. Equipment utilized in extreme atmospheres may need to be immune and sturdy to dirt, dampness, or severe temperature levels.

One more essential variable is the modern technology used in the scales. Digital ranges commonly use improved accuracy and convenience of use, while analog ranges might be enough for less demanding applications. special info In addition, it is very important to examine the scalability of the equipment, ensuring that it can suit future growth or changes in manufacturing processes.

Finally, organizations should think about the online reputation and dependability of suppliers, as purchasing top notch devices can bring about long-term price savings and enhanced functional effectiveness.

Maintenance for Long Life

Regular maintenance is crucial for making sure the long life and optimal performance of commercial ranges. A systematic technique to upkeep not only extends the life of the devices yet additionally guarantees accurate measurements critical for operational efficiency.

Begin with routine assessments to recognize wear and tear, guaranteeing elements such as load cells and screens work appropriately. Calibration checks should be conducted consistently, ideally after significant modifications in ecological conditions or complying with heavy usage. Accurate calibration is important for compliance with market requirements and for preserving the reliability of weight dimensions.

In addition, it is suggested to establish an upkeep routine that tape-records each service visit, calibration, and any type of repair work performed. This documents aids in monitoring devices efficiency and planning for future maintenance requirements.

Lastly, educating staff on correct usage and treatment techniques will certainly minimize the chance of driver mistake, even more boosting scale integrity. By prioritizing normal maintenance, services can ensure that their commercial ranges stay a trustworthy possession in their operations.

Conclusion

In recap, the assimilation of reliable industrial ranges is important for improving business operations throughout various sectors. Precise evaluating not just minimizes inconsistencies yet also enhances stock monitoring and ensures compliance with market criteria. The option of appropriate equipment, combined with contemporary technical advancements, can considerably enhance effectiveness and decrease functional expenses. Routine upkeep and training additional add to the long life and precision of these ranges, cultivating data-driven decision-making and ultimately supporting overall business success.

Industrial scales come in various types, each made to meet specific weighing demands throughout different sectors. Crane ranges are likewise notable; they are suspended from a framework to consider heavy products in commercial settings.Different sectors might need unique types of ranges, such as flooring scales for Recommended Reading hefty lots, bench scales for smaller sized products, or portable ranges for versatility - Industrial Scales. Digital scales usually supply improved accuracy and convenience of use, while analog ranges may be enough for less requiring applications.In summary, the combination of reputable commercial scales is essential for improving business procedures across different industries

Report this page